Smart Factory

Panasonic Connect provides smart, connected, customizable manufacturing solutions that boost operational efficiency, increase visibility—and further your Industry 4.0 digitization initiatives.

Optimize Every Process for Peak Performance

Ready to unlock smarter, more efficient production? Panasonic Connect helps manufacturers overcome staffing and supply chain challenges while reducing costs, maximizing uptime, and improving product quality through connected, automated solutions that deliver real-time manufacturing insight and control. Backed by our own experience as one of the world’s largest manufacturers, we use these same technologies to drive performance in Panasonic factories every day.

Built on scalable software and intelligent automation, our solutions connect and control equipment—old and new—while tracking materials, optimizing processes, and managing assets across your entire line. Wherever you are on your digital transformation journey, we’ll help you accelerate toward a more connected, autonomous factory.

-

Electronics Assembly

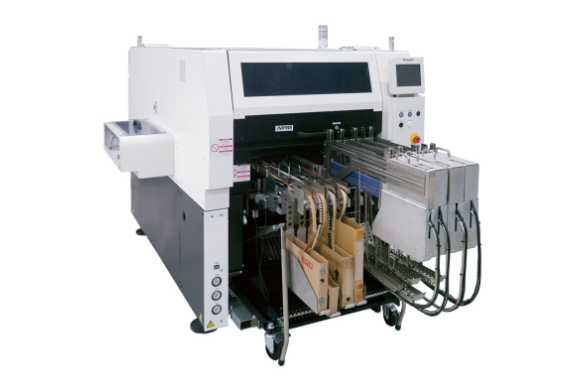

Electronics Assembly Manufacturing Equipment for Surface Mount Technology (SMT), Pin Through Hole (PTH), Odd Form & End of Line, Microelectronics and Metrology, including Screen Printing and Component Placement. -

Welding & Robotics

Since introducing the AC Welding machine with built-in condenser in 1957, Panasonic has been a global leader of arc welding technology—providing high quality welding solutions from power sources to robots to software. -

Services & Software

From AI-powered analytics to predictive maintenance, Panasonic Connect delivers the tools, expertise, and support you need to reduce downtime, cut waste, and power continuous improvement. -

Solutions

From end-to-end production systems to connected software, Panasonic Connect delivers solutions that streamline operations, improve visibility, and keep your factory competitive.

Section Title

Section Summary Text

-

Smart Factory Solutions

Overcome labor gaps, waste, and downtime with smart factory solutions that connect your operations for seamless efficiency, higher output, and greater resilience.

Learn More about Smart Factory Solutions Learn More -

Total Solutions Offering

Streamline production with our Total Solutions Offering (TSO), a fully integrated ecosystem of equipment, software, and support to keep your operation running at peak performance.

Learn More about Total Solutions Offering Learn More -

SyncoraDMP

Boost efficiency and visibility with SyncoraDMP, the MES platform that integrates systems, reduces bottlenecks, and empowers faster, data-driven decision-making.

Learn More about SyncoraDMP Learn More

PanaCIM Software

-

PanaCIM (MES)

PanaCIM Enterprise Edition is a multi-level manufacturing execution system (MES) software solution for any size manufacturer.

Learn More about PanaCIM (MES) Learn More -

Material Management

Realize the efficiencies of reduced labor costs and raw material inventory, and maintain optimal profitability by minimizing downtime.

Learn More about Material Management Learn More -

Asset Performance Maintenance

Complete tracking solution for assets, maintenance work and spare parts.

Learn More about Asset Performance Maintenance Learn More

Featured Products

Screen Printers

PTH, Odd-Form & End of Line

Microelectronics

Metrology

Order Parts, Support & Consulting

As a manufacturer, Panasonic Connect understands the evolving demands of today’s electronics assembly environment. While quality equipment and the right MES software are part of the equation for maximizing factory productivity, total manufacturing solutions also require a broad technical support network and other products and services that can keep your lines running and profitable.

From online training and technical assistance on the phone to a global service team ready for dispatch, our support team can aid with basic questions and initial setup to break-fix situations and provide preventative maintenance. Process solutions for reducing scrap and rework costs or other big-picture concerns are accessible through our Enterprise Consulting team.

To help keep your placements accurate and reduce overall downtime we offer solutions for calibration and certification. And if you staff needs any additional skills, training can be provided for equipment and software either in-person or online. OEM Parts and quick-turn-around custom nozzles as well as lower-cost rebuilt feeders and purchasing programs can help you find the right tools for your application.

-

Order Parts & Custom Applications

Insist on Genuine Panasonic OEM parts to maximize your equipment’s performance. For standard parts, eCommerce is available 24/7 for your convenience. For custom applications and personal service, you can reach our team during business hours. -

Support & Training

We offer scalable support and technical assistance with our global service team ready for dispatch and a Technical Assistance Center that can aid with basic questions and initial setup to break-fix situations. -

Lean Manufacturing Consulting

Our Lean Manufacturing Consulting services and training classes are designed to help you to get maximum return from your capital equipment investment by making products flow through your value-added processes without interruption.

Panasonic Connect Total Solutions Offering (TSO)

Explore Panasonic Connect's Total Solutions Offering for smart manufacturing solutions that boost efficiency, reduce risks, and promote sustainability across your production operations.

Welding Equipment & Robotics

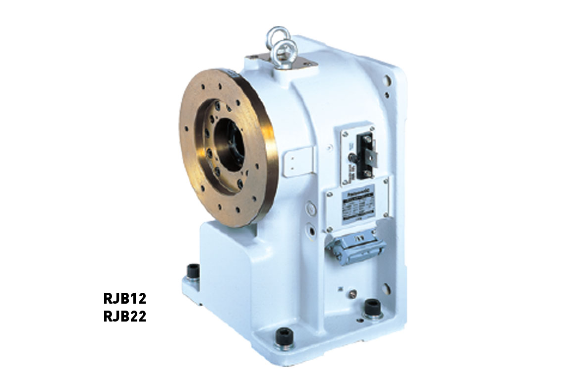

Since introducing the AC Welding machine with built-in condenser in 1957, Panasonic has been a global leader of arc welding technology—providing high quality welding solutions from power sources to robots to software.Welding Software

-

DTPS III Desktop Programming & Simulation

Panasonic’s globally-deployed desktop software package that allows users to fully design and edit welding functions in 3D.

Learn More about DTPS III Desktop Programming & Simulation Learn More -

Heavy Plate Software

Software for Middle Plates and Thick Plates adds increased arc sensor functionality for high current and pulse welding to your operation.

Learn More about Heavy Plate Software Learn More

Featured Products

Arc Welding Systems

Robots

Positioners

SyncoraDMP™

Synchronizing digital manufacturing platform for today's manufacturers.

The demand for efficient and high-quality EV battery production is growing rapidly. To meet this demand, manufacturers need reliable partners with deep industry knowledge and advanced technological solutions.

Panasonic Connect offers highly reliable electronics assembly software & equipment for the surface mount technology (SMT), pin through hole (PTH), and microelectronics back-end packaging processes of any-mix circuit manufacturing. From screen printers and dispensing, high-speed component placement and inspection, to axial and radial insertion, die bonding, die attach and flip chip, we provide MES software & IoT enabled equipment that is used all over the world to maximize production output.

Take a virtual 360° tour of our factory solutions and see how you can transform your factory

Contact Us

Smart Factory | US Business Sales & Support

Want to contact sales or need support with your Smart Factory product? Use the link below to get in touch with a member of our US Sales or Support team.